Water Treatment Application Type

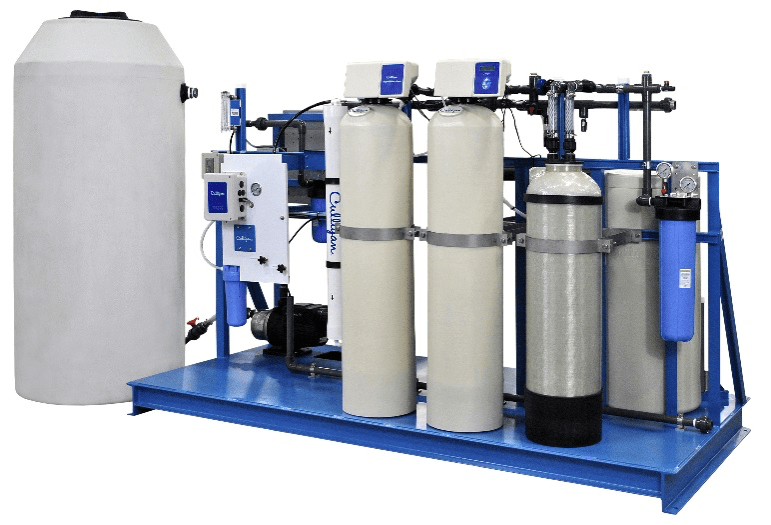

Industrial water treatment solutions from Culligan

With over 85 years of experience, Culligan Water specializes in industrial water treatment, providing customized solutions for manufacturing, oil

and gas and engineering sectors. Utilizing advanced technologies like reverse osmosis and filtration, Culligan optimizes water quality and equipment performance. Our services include water analysis and tailored treatment system design, focusing on exceptional customer service to enhance water quality, efficiency and compliance with industry regulations while reducing downtime and costs.

Industrial applications for water treatment

Oil & Gas

Culligan offers cutting-edge water treatment solutions tailored for the oil and gas sector, with a strong emphasis on sustainability and telemetry. Our environmentally friendly technologies prioritize reducing water consumption while also minimizing environmental impact through effective water reuse and recycling. Moreover, our telemetry features facilitate remote monitoring and management of water treatment systems. This collection of real-time data supports proactive maintenance, enhances performance, reduces downtime and ultimately lowers costs while improving overall workflow efficiency.

Power & Energy

Ensure your facility operates smoothly while boosting profitability and reducing chemical expenses. If you aim to lower wastewater discharge, enhance energy efficiency or implement drinking water systems for your business, Culligan can tailor a solution that is designed and installed swiftly to help minimize operating costs. We offer dependable and sustainable solutions, ranging from advanced filtration systems to water softeners and reverse osmosis units, all aimed at helping you

conserve resources and improve productivity.

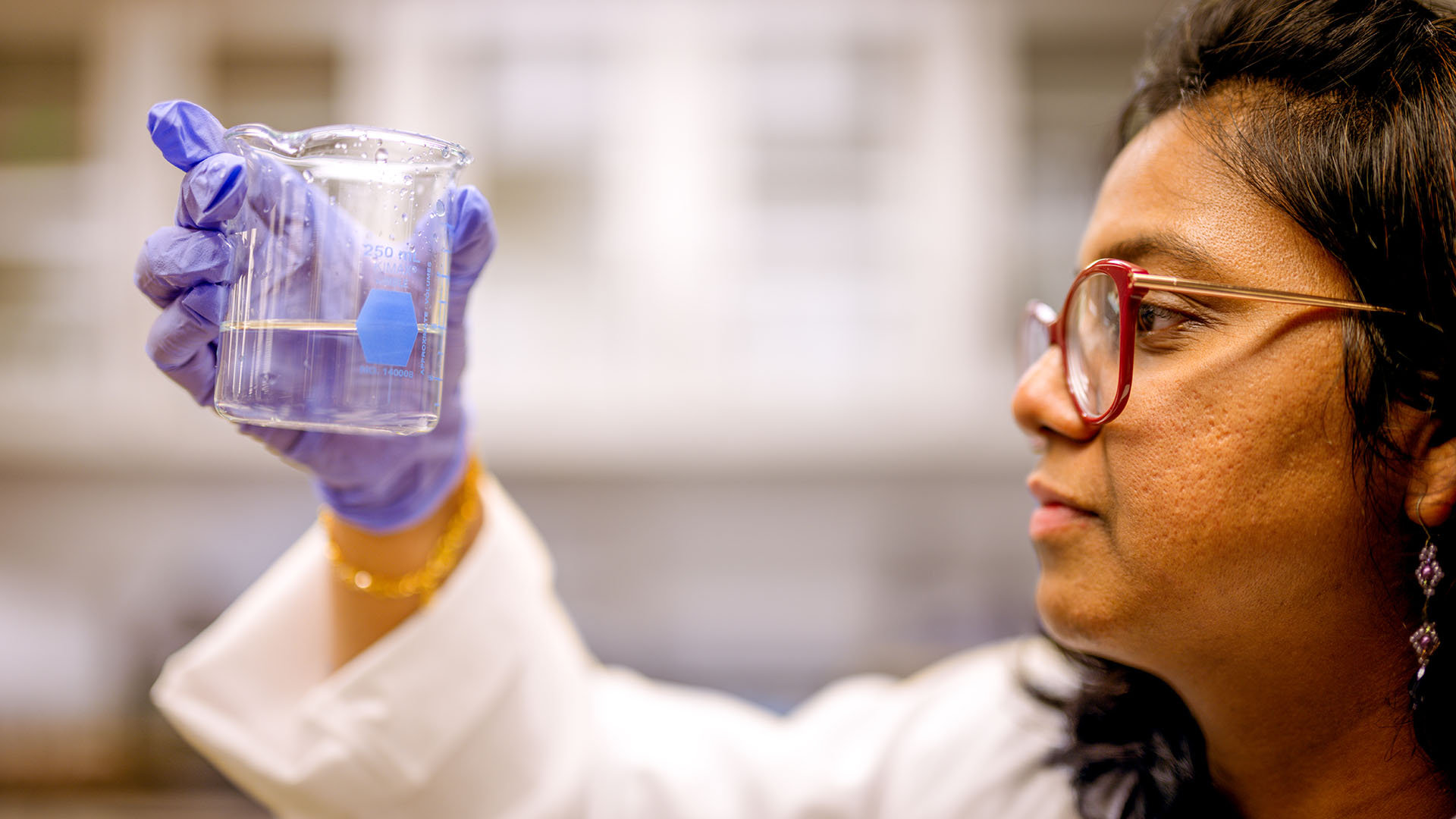

Laboratories

Ensure your laboratory runs seamlessly while maximizing operational efficiency and minimizing chemical and water-related expenses. Whether you are looking to meet strict water purity standards, reduce wastewater output, or support energy-efficient operations, Culligan can engineer a customized water solution that meets the exacting demands of your lab environment. We provide reliable and sustainable systems, including high-purity water filtration, reverse osmosis, and deionization units, designed to support critical testing, reduce contamination risk, and extend the life of your sensitive equipment, all while helping you control costs and stay compliant.

Chemical Processing

In chemical processing, water quality directly impacts product integrity, equipment longevity, and operational efficiency. Culligan delivers customized water treatment systems that help you reduce scaling, corrosion, and downtime, so your facility can operate at peak performance. From industrial water softeners and reverse osmosis systems to wastewater treatment and recovery solutions, our dependable and scalable technologies are designed to lower chemical usage, minimize waste, and improve overall process reliability, keeping you compliant and cost-effective.

Water Treatment

Water treatment facilities require precision, reliability, and adaptability to meet evolving regulatory standards and environmental demands. Culligan partners with municipal and industrial facilities to deliver advanced, customizable solutions that optimize system performance and water quality across every stage of treatment. Whether you need pre-treatment, process water solutions, or support for sludge reduction and reuse, our technologies, including filtration, softening, and reverse osmosis, are built to enhance efficiency, extend equipment life, and ensure compliance with confidence.

Manufacturing

Ensure your business operates more efficiently with water that matches your dedication. Culligan’s commercial and industrial water treatment systems are designed to minimize maintenance costs on parts and equipment, enhance system efficiency and conserve water in the process. Offering a variety of customizable solutions tailored to the specific needs of your operations, Culligan guarantees optimized water quality, resulting in a more streamlined and productive workflow. Our advanced technologies, ranging from water softeners and filtration systems to reverse osmosis and deionization, are built to address even the most challenging water issues.

and more...

We understand that each business has unique water quality requirements. Culligan can customize a solution that meets your water treatment concerns within your budget, time frame and sustainability goals.

Oil refinery case study

Oxy | Sundown, Texas and Denver City, Texas

Problem: With the expansion of production at multiple plants, Oxy faced critical water quality issues with raw water containing very high levels of TDS (1500 ppm), hardness (30 gpg), sulfates (500+ ppm), and chlorides (700+ ppm). This water was unsuitable for emissions systems requiring TDS below 25 ppm and posed risks of damage to boilers. Oxy needed a reliable water treatment solution to ensure regulatory compliance and protect their operations.

Solution: To address Oxy’s water treatment challenges, Culligan performed an on-site evaluation and designed a multi-stage filtration system tailored to remove contaminants and meet water quality requirements. The system included two Hi-Flo 50 softeners to reduce hardness, one Hi-Flo 50 depth filter for suspended solids removal, and a 100 gpm G3 reverse osmosis system to lower TDS, sulfates, and chlorides to acceptable levels.

Results: After installing Culligan’s advanced water treatment system, Oxy achieved significant results: consistent regulatory compliance with TDS levels below 25 ppm, increased production capacity without interruptions, and effective boiler protection ensuring longevity and efficiency. The reliable water supply supported uninterrupted operations. Culligan’s tailored solution enabled Oxy to overcome critical water quality challenges and meet their operational objectives.

Oil and energy industry case study

Endeavor | Lenore, Texas

Problem: Endeavor, operating multiple field offices near remote Lenore, TX, faced severe water quality challenges due to limited infrastructure and hazardous groundwater conditions. The water contained dangerously high arsenic levels—over 2000 times EWG limits—as well as elevated total dissolved solids (2300 ppm), extreme hardness (70 gpg), arsenic at 10.5 ppb, and sulfates above 500 ppm. These issues posed serious health risks, requiring a robust and effective water treatment solution.

Solution: Endeavor enlisted Culligan to deliver a custom multi-stage water treatment system featuring chlorination, high-capacity pumping, particulate and chlorine filtration, chemical scale prevention, primary and secondary reverse osmosis, arsenic removal, and corrosion control—ensuring effective purification and wastewater recycling.

Results: Culligan’s system delivered outstanding results for Endeavor, reducing contaminants to non-detectable levels and lowering TDS to 48 ppm. The secondary RO system enabled 50% wastewater recycling, cutting environmental impact and disposal costs. The solution provided a reliable, consistent supply of safe water for employees. Overall, Culligan’s custom design effectively met Endeavor’s complex water challenges, ensuring safe drinking water and promoting sustainability.

Chemical industry case study

Champion X | Midland-Odessa, Texas

Problem: Champion X, a chemical blending company in West Texas, faced a critical challenge due to severely compromised local groundwater. The well water had high total dissolved solids (1700 ppm), significant hardness (26 gpg), elevated suspended solids (SDI of 14), and detectable chlorine (2 ppm). Additionally, the facility lacked wastewater disposal infrastructure, requiring costly truck hauling. Champion X needed an efficient water purification system that could deliver high-purity water while minimizing waste under these challenging conditions.

Solution: Culligan designed and implemented a tailored multi-stage water treatment system for Champion X, including pre-softening with multiple high-capacity softeners, two VFD supply pumps, chemical injection for silt removal, a 14-inch depth filter for suspended solids, portable carbon filters for chlorine removal, a 6 gpm primary RO system for high-purity water, and a 3 gpm secondary RO system to recycle wastewater and minimize waste.

Results: Culligan’s tailored solution provided Champion X with exceptionally pure water by reducing chlorine, hardness, SDI, and TDS to near non-detectable levels (TDS ~6 ppm). The system’s wastewater recovery RO reduced waste volume by 50%, lowering disposal costs. Designed for West Texas’ extreme conditions, the solution ensured reliable operation, enabling Champion X to maintain high production standards while reducing environmental impact and operational expenses.

Manufacturing industry case study

Gandy’s | Lubbock, Texas

Problem: Unlike fluid milk, tea and juice production depends heavily on water as a key ingredient, requiring strict water quality. Gandy’s Dairies needed to eliminate chlorine, chloramine, and off-flavors from municipal water, ensure consistent high-quality water for their production line, and meet Quality Chekd® standards. They required a high-flow filtration system to support commercial-scale operations and production goals.

Solution: Culligan delivered a customized industrial-grade filtration system for high-volume beverage production, featuring the CSM™ Heavy Duty 422 R Triplex Carbon Filter to remove chlorine and impurities, a micron final filter for fine particulate removal, and a Smart Controller with advanced diagnostics to ensure efficiency and consistent water quality. The system supports up to 200 gallons per minute to meet production demands.

Results: The installation of Culligan’s system enabled Gandy’s Dairies to achieve superior water quality by removing taste and odor contaminants, enhance operational efficiency through advanced system management, and successfully launch a new line of bottled teas and juices meeting strict quality standards. This expansion increased revenue and reinforced Gandy’s brand reputation under Quality Chekd® standards. Culligan’s high-capacity filtration solution provided reliable, cost-effective water quality to support Gandy’s product growth without compromising their established standards.

Chemical industry case study

Global Leader in the Performance Chemical Industry

Problem: A water solution was essential to ensure the provision of pure water as an ingredient for a key product for this chemical plant. The main concern was that this product occasionally displayed discoloration and the development of precipitates after being stored on the shelf for 3 to 5 months, leading to customer returns. Addressing this issue became a top priority for the company, renowned for its commitment to exceptional product quality.

Solution: Containerized reverse osmosis system with a brine collection and recovery system.

Results: The customer observed a significant reduction in off-spec material and returns, along with an increase in production, which helped to balance the costs of Culligan's monthly long-term lease/service model. While the main goal was to minimize off-spec products in a particular offering, the customer also benefited from a decrease in off-spec material across different product lines, a 23% increase in processing time for several operations due to improved water quality, fewer returned goods, and a remarkable 73% reduction in waste generation, thereby negating the necessity for a new waste handling system.

Manufacturing & printing case study

RR Donnelley

Problem: RR Donnelley faced intermittent hard water breakthrough in their cooling tower caused by low flow and unbalanced plumbing, leading to increased chemical use, higher water consumption, operational inefficiencies, and elevated treatment costs. Their primary goal was to reduce chemical expenses and water waste while maintaining consistent softened water flow to the cooling system.

Solution: Culligan installed a triplex metered softener system with progressive flow control and balanced plumbing, allowing one vessel to operate during low demand and automatically adding units as flow increased. This ensured consistent, fully softened water while preventing hardness breakthrough. The system included a GBE Smart Controller for performance monitoring.

Results: Culligan’s solution delivered immediate benefits to RR Donnelley, including a 37% reduction in salt usage—resulting in significant cost savings with a 27-month payback, alongside a 35% decrease in chemical consumption. The GBE Smart Controller enhanced system insight through actionable diagnostics, enabling optimized cooling tower performance. Overall, Culligan’s advanced softening system reduced operating costs, conserved resources, and improved efficiency, providing a sustainable, cost-effective water treatment solution.

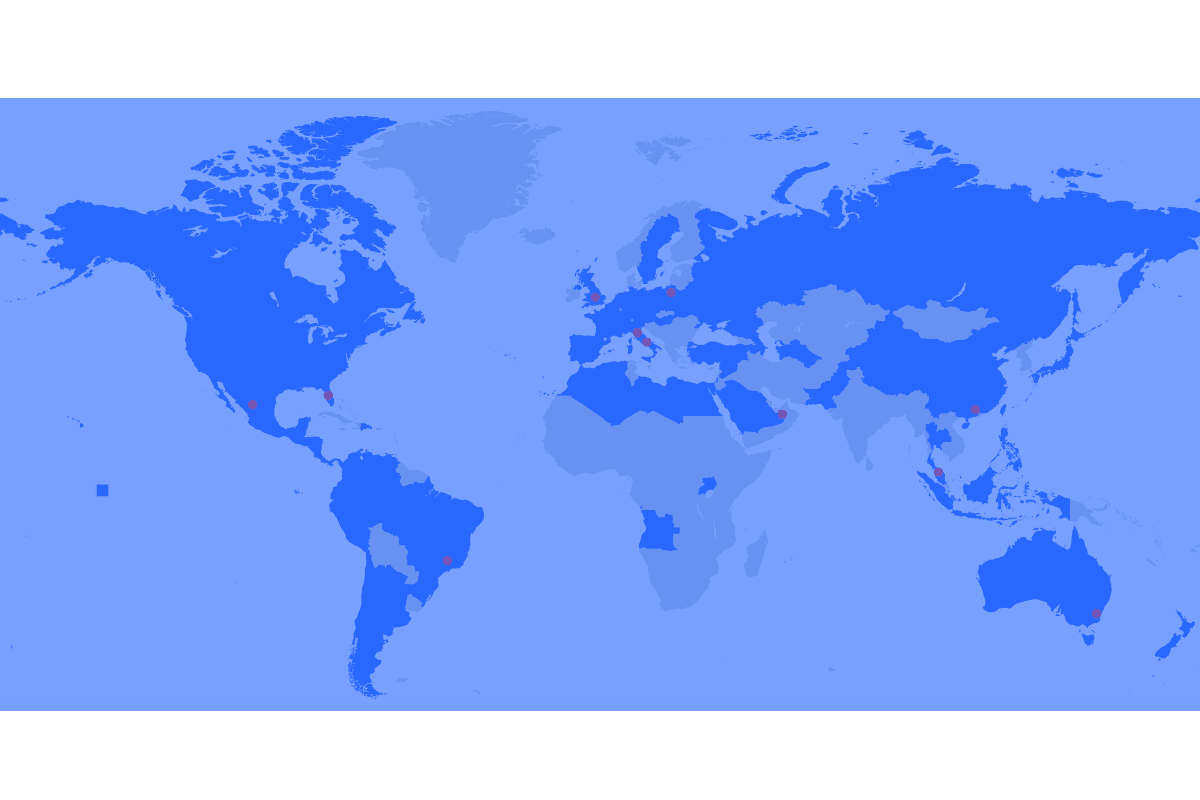

Unrivaled Global Network

Let Culligan take care of your water. You take care of your business.

As the industry leader for more than 85 years, Culligan understands the significance of high-quality water for your business. Our industrial equipment caters a wide range of industries worldwide. With Culligan’s commercial and industrial water systems, you can eliminate excessive equipment maintenance, low flow rates, and high operating costs.

Challenges of untreated water

20-30% Reduced Lifespan

Increased equipment wear & tear such as scaling & corrosion

5-15% Decreased Production Efficiency

Frequent downtime, reduced production quality

5-10% Increased Material Costs

Increased water and chemical usage

Up to 30% Raised Maintenance Costs

Increased fuel & energy costs and maintenance expenses

Unmatched Culligan solutions

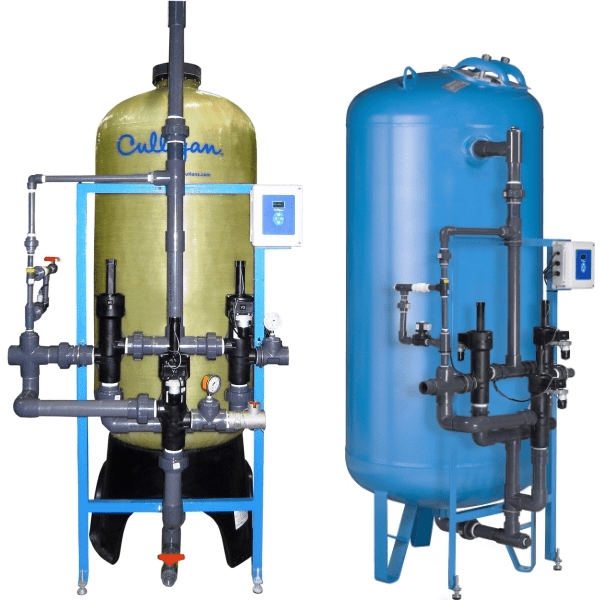

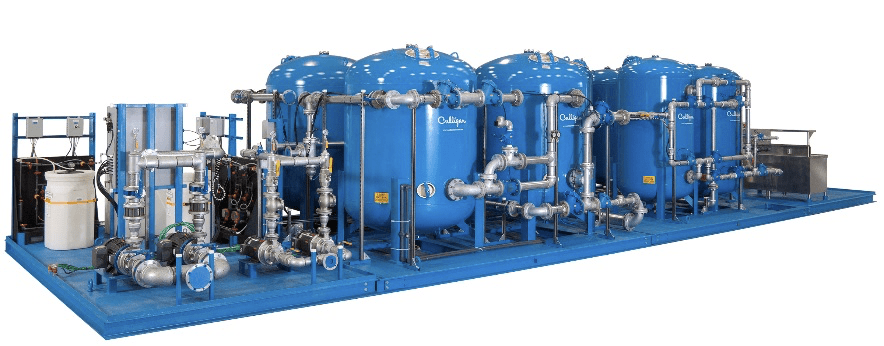

Water Filtration & Softening

Culligan offers a range of water filtration and softening systems, including sediment, carbon and specialty filters, aimed at improving both water quality and taste. Additionally, Culligan water softeners effectively eliminate hardness minerals, which helps minimize scale buildup and enhances the lifespan and efficiency of your equipment.

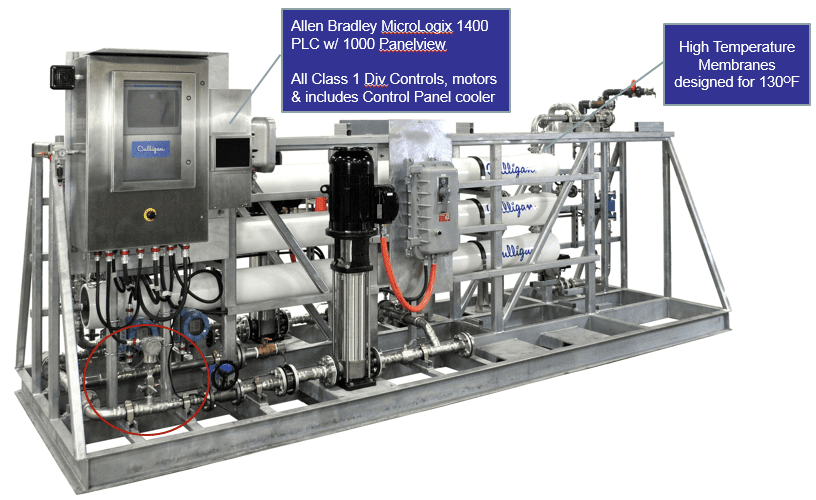

Reverse Osmosis

Culligan offers a range of water filtration systems, including sediment, carbon and specialty filters, aimed at improving water quality and flavor. Their reverse osmosis systems effectively eliminate dissolved solids and contaminants, making them suitable for industrial applications.

UV Disinfection

Culligan UV disinfection systems harness ultraviolet light to eliminate microorganisms in water, enhancing protection against waterborne pathogens. Additionally, they provide chemical treatments to address challenges such as scale control, corrosion and microbial growth. This includes dosing systems, oxidizing agents and pH adjustment systems.

Telemetry & Automation

Culligan provides Telemetry and Automation solutions designed for water treatment systems. Telemetry allows for remote monitoring and control, delivering

real-time insights into performance and water quality. Automation utilizes this data to adjust settings and execute tasks, enhancing efficiency and ensuring

consistent quality. These solutions improve operations, reduce downtime and elevate overall performance in water treatment.

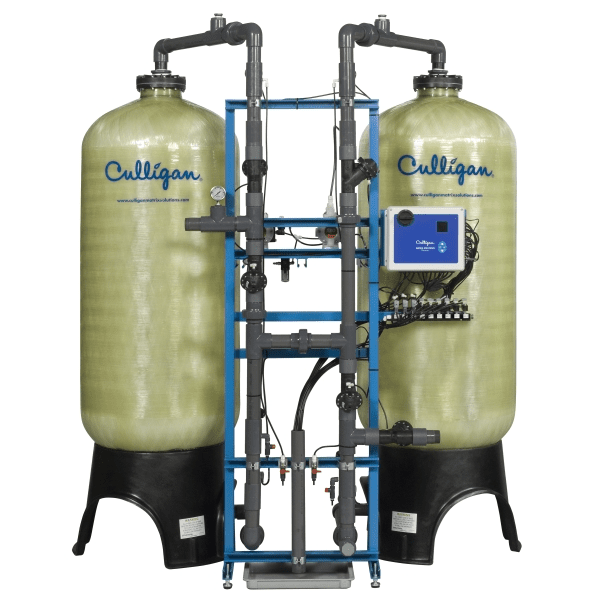

DI Systems

Culligan deionization systems utilize ion exchange technology to eliminate dissolved minerals and ions from water, generating high-purity water suitable for specialized industrial applications that demand ultra-pure water.

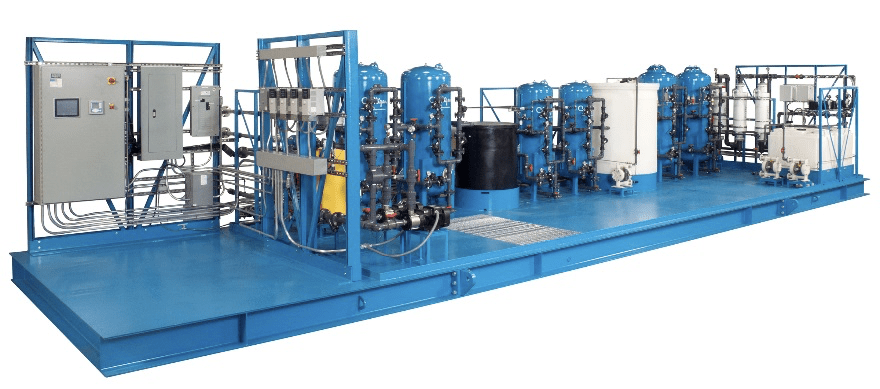

Customized Systems

Culligan works hand in hand with commercial and industrial businesses to design customized water treatment systems that address their unique needs. These

systems can be specifically adapted to resolve particular water quality challenges, comply with regulatory requirements and improve operational efficiency.

Service and Maintenance

Culligan offers thorough service and maintenance for their water treatment systems. Our skilled technicians conduct regular check-ups, system inspections and preventive maintenance to guarantee optimal performance and extend the lifespan of the equipment.

Consulting Services

Our experienced consultants work closely with your team to assess system performance, identify opportunities for improvement and ensure compliance with industry standards. From system design and specification to process optimization and cost analysis, we provide the insight and guidance you need to achieve efficient, sustainable water management.

Why Choose Culligan

Expertise

Culligan has been a pioneer in the water treatment sector for more than 80 years. They possess vast expertise and experience in delivering water treatment solutions across a range of industries and applications.

Advanced Technology

Culligan employs state-of-the-art water treatment technologies to provide premium quality water. Their products are designed with innovative features and advanced filtration systems that effectively eliminate impurities and contaminants.

Customized Solutions

Culligan recognizes that every industrial or commercial application has distinct water treatment requirements. They provide personalized solutions designed to meet these specific needs, guaranteeing the best water quality and efficiency.

EPA Certified Analytical Laboratory Service

Request Consultation

Culligan's consulting approach

Our consultative approach involves a Culligan professional assessing your specific water quality requirements. We specialize in solutions for energy, oil and power plants, using advanced technology to save money, improve ROI and support sustainability. Whether addressing boiler feedwater, cooling tower optimization or wastewater management, our team delivers innovative results while ensuring regulatory compliance. Partner with Culligan for expert management of your water systems and a more sustainable, profitable future.

Trusted and Proven to Serve

Culligan’s Commitment to Safety and Regulatory Compliance

Commercial & Industrial Water Treatment Products

Commercial Water Softeners

Uses an ion exchange process to remove calcium, magnesium, iron, manganese and other dissolved minerals from your water.

Prevents mineral and scale build-up for increased lifespan of your equipment and fewer operational interruptions

Easier cleaning with fewer chemicals and detergents

Less scaling on heating and cooling systems, which means energy conservation

Brine reclamation means less high-concentrated wastewater

Dealer participation varies. See dealer for details.

Commercial Water Filters

Uses multi-step filtration to remove impurities and contaminants from your water.

Better-tasting water for food and beverage consumption

Extends the life of your water-using appliances and equipment

Ultrapure water complies with government regulations for some industries

High-quality drinking water for employees, customers and guests improves well-being and satisfaction

Dealer participation varies. See dealer for details.

Commercial Water Deionizers

Uses an ion exchange process to remove cations (like calcium, magnesium and sodium) and anions (like chloride, sulfate and nitrate) from your water.

High purity water ensures products and processes are free from contaminants and impurities

Allows your business to comply with governmental and industry regulations

Reduces the need for frequent cleaning of equipment with harsh chemicals

Prevents scale buildup, corrosion and contamination in equipment and machinery

Dealer participation varies. See dealer for details.

Commercial Dealkalizers

Uses an ion exchange process to remove bicarbonates, carbonates and hydroxides from your water.

Increases the lifespan of equipment, pipes and valves

Reduced scaling and corrosion results in in less cleaning and lower contamination risks

Easier heat transfer in heat exchangers and other thermal systems

Minimal downtime for routine maintenance and reduced labor costs

Maintain control of water's pH levels to meet strict regulatory standards

Dealer participation varies. See dealer for details.

Commercial Reverse Osmosis Systems

Uses multi-step membrane filtration to remove impurities and contaminants from your water.

High purity water ensures products and processes are free from contaminants and impurities

Improved performance and efficiency of water-using equipment

Allows your business to comply with governmental and industry regulations

Better-tasting food and beverages like coffee, beer, and wine

Dealer participation varies. See dealer for details.

Commercial Ultraviolet (UV) Water Purifiers

Uses ultraviolet light exposure to remove bacteria and other microbiological contaminants, as well as chlorine, from your water.

Provides immediate disinfection for pathogen-free water for consumption

Easily integrated into existing water treatment systems for added protection

Requires less energy compared to other disinfection methods

Minimal maintenance and no additional fees for filters or cleaning chemicals

Dealer participation varies. See dealer for details.

Does your business need better water?

Save time, money and your equipment with Culligan Commercial Water.

Let our engineers develop the right water treatment solution for you.

Contact our commercial water team

Request a FREE consultation with one of our engineers to get started.

Thank you for contacting us!

One of our representatives will contact you shortly.

We ran into an issue submitting your form, please call

866-330-4482

to connect with your Culligan Dealer.